Before Creating Equipment Work Centers in SAP, let’s start by SAP PM Equipment Creation: Equipment is an individual and physical object that is maintained as an autonomous unit. Maintenance history and cost can be tracked historically.

This article is an step by step tutorial to creation an equipment in SAP PM.

Creating Equipment in SAP PM

SAP PM Equipment Creation Tcode IE01

The SAP Tcode to create SAP PM ( Plant Maintenance) Equipment is IE01: Create Equipment.

Naturally, IE02 is the Transaction code to Modify SAP PM Equipment

and IE03 is for Display of Equipment in SAP PM.

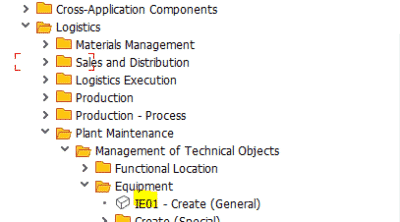

An alternative way for the IE01 is to navigate through the SAP Menu in SAP GUI ( as shown bellow )

Go to Logistics > Plant Maintennace > Management of Technical Objects > Equipment > IE01 ( General )

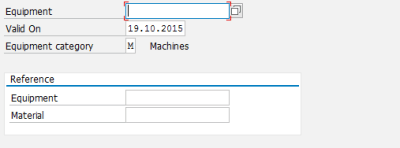

Select the Category of the Equipment and a Valid from

- For Valid From: it is the date where the Equipment will be activated.

- For Category: it helps to classify the SAP PM Equipment.

By defaut, the Category M ( for Machines) is selected.

You can select other values. The standard Equipment Categories in SAP PM are:

| Equipment Category | Description |

|---|---|

| M | Machines |

| P | Production resources/tools |

| Q | Test/measurement equipment |

| S | Sales equipment |

Note that if you want to maintain SAP PM Equipment Category, you have to go to

SPRO – Plant Maintenance and Customer Service -> Master Data in Plant Maintenance and Customer Service -> Technical Objects -> Equipment -> Equipment Categories -> Maintain Equiment Category

For SAP PM Equipment Category, I recommend this post.

Check also SAP Equipment Tables ? Main List of Equipment Tables in SAP.

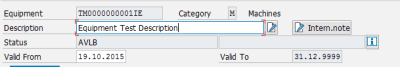

Fill Equipment’s Description

It is the description of a technical object in the form of a short text and you can fill up to 40 caracters.

You can also add a long text for the Equipment if you click in the ‘create text’ next to Description field ( it is not mandatory ).

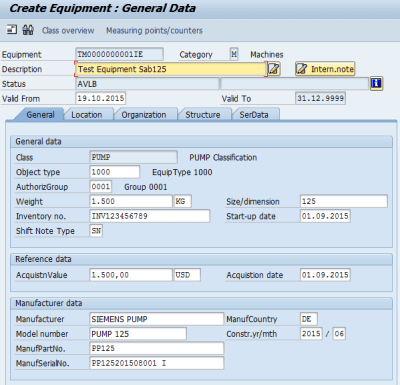

Configure General Data Tab

Equipment General Data Tab is divisied into 3 blocks:

General Data

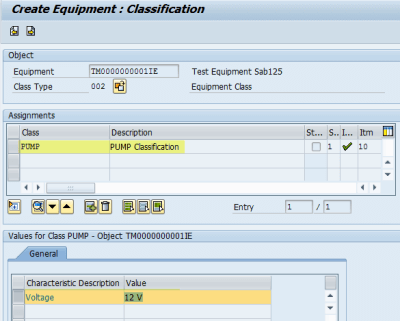

For the first Field, Equipment Class (KLASSE), it is Display only. You can set the Equipment Class by clicking the Class Overview in the Bar menu.

Select the Class Type 002 for Equipment Class and then maintain the value for Class.

Read also SAP Equipment Exit, BTE and BADI for SAP Tcodes IE01/IE02.

Class is important in order to maintain Characteristics of Equipment by type of Equipment ( ex: metrics, Motors, Machines, … ).

For sample, the following Equipment is classed as “Pump” and a “voltage” characteristic can be set:

The second Field is the Object (ITOB-EQART). It is the key that describes the type of technical object. A division of a technical object for precise description.

For Equipment Category M ( Machines, Technical Types can be Turbine, Motor, …

The next field is Authorization Group (ITOB-BEGRU): it is a technical object in Plant Maintenance. You can restrict acces to this Equipment for a limited users profils if set. For exemple, Electronical Equipments will be visible only for Electric’s users population.

Weight (ITOB-BRGEW and GEWEI), Size/dimension (ITOB-GROES), Inventory number (ITOB-INVNR), Start-up Date of the Technical Object (ITOB-INBDT) can be maintained next.

Reference Data

It is important to fill the Acquisition Value (ITOB-ANSWT) in order to compare the cost of Equipment maintenance and the cost of Acquisition to decide to keep the equipment or remplace it.

The Acquisition Date (ITOB-ANSDT) is also an important information for the Equipment livecycle.

Manufacturer Data

This block regroups the Equipment manufacture.

Manufacturer (ITOB-HERST) of asset You can enter the manufacturer of the asset in this field.

This field is currently for informational purposes only but it is very important. In fact, the standard Report MCI2 (PMIS: Manufacturer Analysis) gives an analysis of the equipments based on Manufacturer.

Country of manufacture (ITOB-HERLD) and Manufacturer model number (ITOB-TYPBZ), Year (ITOB-BAUJJ) and month of construction (ITOB-BAUMM) can also be maintained.

In order to facilitate the communication with the manusfacture fill the Manufacturer part number (ITOB-MAPAR) which is given to the technical object by the manufacturer and which allows him to manage objects of the same category.

The serial number is the number that is assigned by the manufacturer for an individual technical object: Manufacturer serial number (ITOB-SERGE).

One the General Data is filled, The Equipment first tab will look like:

Bravo ! The Equipment can be saved with the General Data filled. An Equipment number is generated (based on SAP Range defined in customizing).

Check also Create single Material Document with Multiple Equipment.